Little Known Questions About Lean Manufacturing.s

Wiki Article

Some Known Details About Hon Hai Precision

Table of ContentsThe 4-Minute Rule for Die CastingSee This Report about Manufacturing IndustriesThe Main Principles Of Lean Production The Definitive Guide for Manufacturing IndustriesThe Ultimate Guide To Lean Production3 Easy Facts About Manufacturing Explained

The message on this web page is an example from our complete White Paper 'Shot Moulding for Purchasers' - * Sample text * - for full guide click the download button above! Introduction This guide is intended for individuals that are wanting to source plastic mouldings. It provides a much needed insight into all that is involved with creating plastic components, from the mould device called for to the moulding process itself.If you wish to discover better, the guide covers kinds of mould tools, in addition to special completing processes such as colours & plating. Words that are underlined can be located in the reference in the appendix ... Component I: Moulding: The Fundamentals The Advantages of Injection Moulding Plastic shot moulding is a really precise procedure that offers several advantages over various other plastic handling techniques.

Accuracy is ideal for really detailed parts. You can hold this moulding in the hand of your hand as well as it has bosses, ribs, steel inserts, side cores and openings, made with a sliding shut off feature in the mould tool.

Not known Facts About Manufacturing

Getting My Plastic Manufacturing To Work

from material feed & melting; material injection; cooling time cooling down ejection to the re-closing of the mould tool ready device all set next cycleFollowing Draft angles - The wall surfaces of a moulded component must be a little tapered in the instructions in which the component is ejected from the mould tool, to allow the part to be expelled quickly.Ejector stroke - The pressing out of ejector pins to eject the moulded part from the mould device. Ejector stroke rate, length and timing needs to be carefully managed to avoid damage to the ejectors and mould tool, however at the very same time make the moulding cycle as short as possible.

The Facts About Oem Uncovered

Ribs - When a plastic component has thin walls, ribs are contributed to the style to make the thin walls stronger Side cores - Side action which produces a function on a moulded component, at an opposing angle to the typical opening direction of the mould tool. die casting. The side core requires to be able to pull back as the plastic part can not be expelled otherwise.

Walls - The sides of a moulded part The message on this web page is a sample from our full White Paper 'Injection Moulding for Purchasers'.

Injection moulding is commonly used for producing a variety of parts, from the tiniest elements to entire body panels of cars. Injection moulding makes use of a special-purpose device that has 3 components: the injection system, tsmc 3nm the mould and the clamp.

Excitement About Manufacturing Industries

, with the quantity used of the former being substantially higher.: 13 Thermoplastics are common due to qualities that make them highly ideal for injection moulding, such as ease of recycling, convenience for a large variety of applications,: 89 and also capability to soften and move on heating.In multiple tooth cavity moulds, each dental caries can be identical as well as create the very same parts or can be special and also form several different geometries during a solitary cycle.

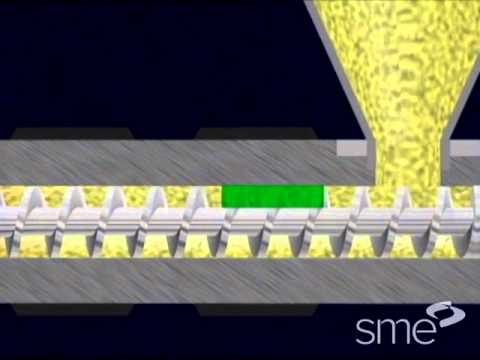

The screw provides the raw material ahead, blends and also homogenises the like it thermal and viscous distributions of the polymer, as well as minimizes the needed home heating time by mechanically shearing the product and also including a substantial quantity of frictional home heating to the polymer. The material feeds forward through a check valve and gathers at the front of the screw into a quantity metal products called a shot. When sufficient product has actually collected, the product is forced at high pressure and velocity into the part forming cavity. The exact amount of shrinkage is a function of the resin being used, and can be fairly predictable. To stop spikes in pressure, the process normally uses a transfer placement representing a 9598% full cavity where the screw shifts from a consistent rate to a consistent stress control.

Manufacturing Industries - The Facts

Once the screw gets to the transfer position the packing stress is applied, which finishes mould dental filling and makes up for thermal shrinking, which is fairly high for thermoplastics family member to several other products. The packaging pressure is applied till eviction (dental caries entrance) solidifies. As a result of its small size, the entrance is normally the starting point to solidify through its whole thickness.: 16 Once the gate strengthens, say goodbye to material can get in the cavity; appropriately, the screw reciprocates and also gets product for the next cycle while the material within the mould cools to ensure that it can be ejected and also be dimensionally secure.Report this wiki page